Food Safety & Quality Management System Insights

Putting Food Safety & Quality First in Your Co-Manufacturer Search

Food Safety and Quality Steps Prior to Contacting Co-Manufacturers Have the process…

Hiring for a Food Safety and Quality Assurance Role

What to Look for in an Applicant What job histories we are…

KPIs for QMS and GFSI Programs

ISO 9001 KPI Requirements For ISO 9001 there are two main sections…

Collecting and Interpreting KPIs

Setting up KPI Data Collection In breaking down data collection for key…

KPIs in Operations

The Most Common KPIs in a Quality Management System The most common…

Setting up Your System for KPIs

Simple measurements for KPIs Vs. Complex Measurements The simplest metrics for performance…

An Introduction into Key Performance Indicators

KPIs are a Tool to Measure Success Most manufacturing businesses have changes…

Webinar Summary – Government Food Safety Inspections

Basis for Government Food Safety Inspections Laws are the source of timeframes…

Responding to an FDA 483 or an FDA Warning Letter

Results of any regulatory inspection, should be reported to senior management, especially…

Key Performance Indicators in Manufacturing and Processing

How to Choose KPIs for Your Manufacturing or Processing Business The KPIs…

How to Implement FSMA 204 FDA Traceability Rule

Which Food Businesses Must Comply with FSMA 204 FDA Traceability Rule? Businesses…

Manufacturing Extension Partnership Helps Companies Access Resources and Grants

What Services do MEP Centers Provide? MEP centers provide services in the…

Amazon Food Safety Expectations for Suppliers

The Amazon requirement for third-party food safety certification applies to: Chilled and…

Backflow Preventers in Food Industry Facilities

What is a Backflow Preventer and Where are They Needed? Backflow preventers…

Food Facility Handwashing Requirements

What is required by the FDA? The Food and Drug Administration’s 21…

Food Facility Restrooms: Requirements and Best Practices

What are the Restroom Requirements for GFSI Facilities? Several GFSI schemes (i.e….

Internal Audit Preparation Webinar – Recording and Summary

Internally Auditing to a Standard If you are desiring for your facility…

Top 12 Grocery Stores & Retailers Requiring Food Safety Audits for Suppliers

Albertsons Food Safety Audit Expectations According to Albertsons, all food and food-contact…

Food Safety Requirements for Selling Your Products at Walmart

Walmart Food Safety Requirements Walmart and Sam’s Club provide their food safety…

Whole Foods Market Suppliers Need Food Safety Certification

Six Steps to Prepare for Your Whole Foods Market Food Safety Certification…

What is HACCP Compliance vs. a HACCP Certificate vs. HACCP Certification?

HACCP Compliance HACCP Compliance is a requirement for facilities that are inspected…

Episode 6: Dietary Supplement Certification

Dietary Supplements Differ from Food As we have reviewed throughout this series,…

Episode 5: GMPs in a Dietary Supplement Program

Hygiene Programs While your facility may have one set of processes to…

Episode 4: Testing in Dietary Supplement Operations

What we are Testing for Because 21 CFR 111 does not require…

Episode 3: Best Practices for Dietary Supplement Operations

The Master Manufacturing Record The Master Manufacturing Record, or MMR is the…

Episode 2: Regulatory Framework of Dietary Supplements

21 CFR 111 Looking at 21 CFR part 111, there are 16…

Episode 1: Introduction to Dietary Supplement Manufacturing

Definition of a Dietary Supplement According to the FDA, “A dietary supplement…

Episode 1: Introducing Validation and Verification

Definition of Validation & Verification The concepts of validation vs. verification are…

Episode 2: Invalid Processes and Signs of Invalidation

Invalid Processes Invalid processes fail to work because they were either not…

Episode 3: Long Term Planning of Validation & Verification

Validation in our Daily Lives Looking at validation of the larger facets…

Episode 4: Short Term Planning for Validation and Verification

Short-term Validation Assessment Benefits Where the sources of long-term validation in a…

Ep 5: Validation & Verification of Critical Safety & Quality Equipment

Validating Equipment for a Recipe Let’s begin by looking at validation of…

Episode 6: Regulatory Requirements and Challenge Studies

FDA regulated facilities that produce other types of food other than juice…

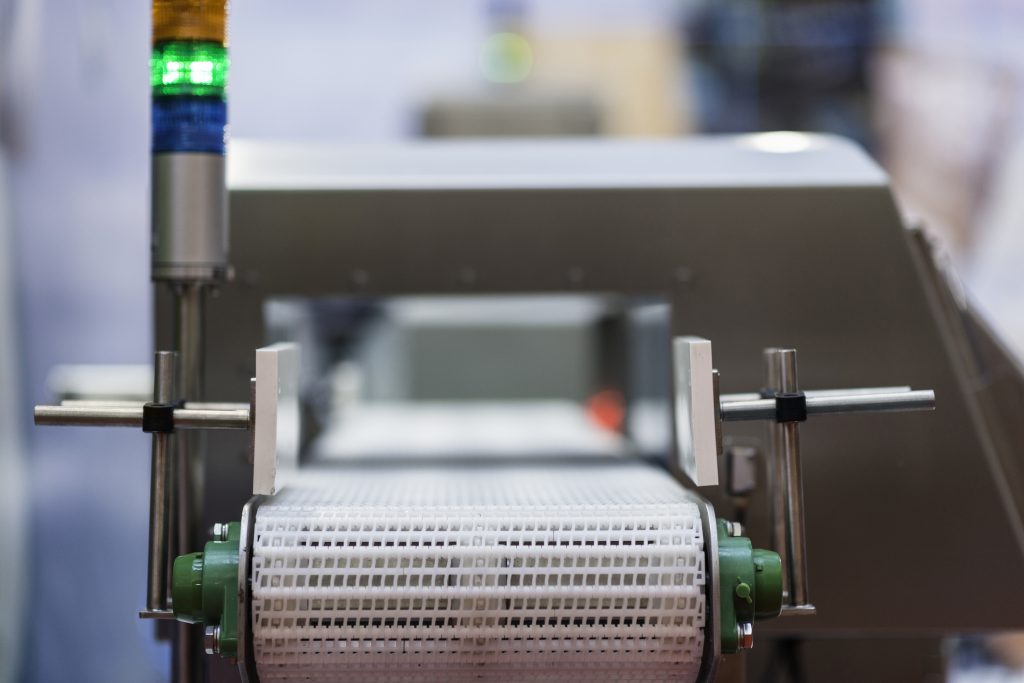

Episode 7: Validation and Verification of Metal Detectors and X-rays

Controversy About X-Rays and Metal Detectors Metal detectors and x-rays are commonly…

Ep 8: Validation & Verification in Quality & Safety Certification Programs

ISO 9001 quality management requirements and GFSI programs operate on many similar…

Free Food Safety & Quality A-Z Acronym Download

Free Food Safety Modernization Act (FSMA) Compliance Checklist

How-to Implement FSMA in a Food Business Kellerman Consulting’s free Food Safety…

Changes to Costco Food Safety Audit Expectations

All Costco Food Safety Audits are moving to unannounced except: Small supplier…

4 Reasons to Choose a Food Safety Consulting Company That Hires Full-Time Employees vs. Contractors

On one hand, there are consulting companies like Kellerman Consulting that only…

Mastering CAPA for QA Managers Webinar

It’s important that you are able to identify control and it is…

Episode 6: Preventive Maintenance and Repair in Quality and Safety Certification Programs

ISO 9001 quality management requirements and GFSI programs operate on many similar…

Episode 5: Worker Safety and Chemical Control

When determining if maintenance and repair activities meet regulatory standards in a…

How to Choose the Right GFSI Certification Scheme for Your Business

What is the Global Food Safety Initiative (GFSI)? The Global Food Safety…

Do you Need a Global Food Safety Initiative (GFSI) Benchmarked Certification to Sell Your Product?

If you are a food manufacturer, food storage and distribution company, food…

Episode 4: Ongoing Repair

The first type of repairs, those stemming from normal wear of the…

Episode 3: Ongoing Preventive Maintenance

The challenges with preventive maintenance mainly have to do with when those…

Episode 2: Maintenance and Repair for New Equipment

Integrating new equipment into a quality and safety management system involves several…

Episode 1: Introduction to Preventive Maintenance

Throughout these episodes, we emphasize where maintenance can be part of continuous…

Episode 5: Allergen Programs in GFSI

Allergen controls are mandatory or fundamental requirements for each of the GFSI…

Episode 4: Allergens in HACCP Plans and Preventive Controls Food Safety Plans

As we look at programs requiring Hazard Analysis and Critical Control Points…

Episode 3: Monitoring Allergens in Operation

In our last episode we discussed locating and labeling allergens in the…

3 Key Updates for BRCGS Issue 9

Behaviors in Quality Culture BRCGS has placed an emphasis on measuring behaviors…

Episode 2: How Allergens Are Controlled in Food Facilities

When a facility is performing these tasks consistently and effectively, allergen management…

Episode 6: Internal Auditing in Quality and Safety Certification Programs

Internal auditing is a mandatory or fundamental requirement for each of the…

Episode #5: Software Solutions for Internal Audits

That means for organizations conducting ISO audit against 9001 or other ISO…

Episode 1: Allergen Risk in Food Facilities

Once we look at the varying risks allergens pose, we will explore…

Episode 4: Corrective Action and Preventive Actions for Audits

In this episode we are going to look at how to properly…

Episode 3: Performing the Audit

Get those flashlights and notepads ready! In order to understand how to…

Episode 2: Setting Up an Internal Audit

Planning and preparation must occur prior to any internal audit in order…

Episode 9: Environmental Monitoring in GFSI Programs

Each of the major GFSI programs, SQF, BRC, FSSC 22000 and PrimusGFS…

Episode 1: What an Internal Audit Is and Why You Should Perform Them

As part of this series we are going to examine what an…

Episode 8: Quality Issues In EMP programs

Since indicator organisms such as Aerobic bacteria and coliforms are allowable in…

Episode 7: How to Handle the Discovery of Pathogens in the Facility

Included in our discussion of a response to these positive results are…

Episode 6: Environmental Swabbing in Meat and Poultry Facilities (FSIS)

In an FSIS regulated facility, and specifically those that process ready-to-eat products…

Episode 5: Complex Swabbing Patterns

An effective environmental monitoring program should have a strategic and at least…

Episode 4: Swabbing Drains in Environmental Monitoring

For operations with drains, and that should be most food and food…

Episode 3: Conducting Environmental Monitoring

Environmental monitoring is intended to mainly monitor non-food contact surfaces near food…

Episode 2: Deciding How often to Perform Environmental Monitoring

The most important issue in determining the frequency of swabbing in a…

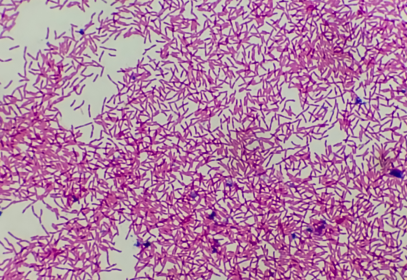

Episode 1: An Introduction to Environmental Monitoring Programs

Let’s begin with the basics of implementing and operating an environmental monitoring…

Episode 5: Risk Assessments in GFSI Programs

Facilities preparing for a certification or recertification audit, review of existing risk…

Episode 4: Risk Assessments as part of the food safety program

As a part of this review, we will be looking at how…

Episode 3: Leadership in Risk Assessment

We will be building on the concepts of how to write a…

Episode 2: Risk Assessments in the Food Facility

First let’s take a look at the parts of operations we want…

Episode 1: Foundations of Risk

We will also address where risk assessments may be useful for business…

Episode #7: Supplier Approval in GFSI

There are many software solutions that make organization much simpler and aid…

Episode #6: Software Solutions in Supplier Assessment Programs

There are many software solutions that make organization much simpler and aid…

Episode #5: Documentation Assessments and Supplier Reassessments

The type of finished product produced at your facility, as well as…

Episode #4: Foreign Supplier Verification Programs for Importers

FSVP is fairly straightforward, but the difficulty with it often stems from…

Episode #3: Regulatory Requirements for Supplier Approval Programs

Regardless of what type of facility we are discussing, the supplier assessments…

Episode #2: Understanding the Types of Suppliers

Each step in the supply chain presents a chance to create a…

Episode 1: Foundations of Supplier Approval

We address who should be leading assessment and approval activities, and how…

Episode 6: Traceability in GFSI

In facilities operating under an SQF program, traceability exercises are required to…

Episode 5: Tests of the Traceability System and Recall Program

A traceability exercise is a test of a site’s entire traceability system…

Episode 4: Traceability During Work-in-Process and Rework

Documenting the use of materials in production can be accomplished by using…

Episode 3: Traceability During Receiving and Stock Rotation Practices

To ensure traceability of materials throughout an operation, a company must document…

Episode 2: Traceability During the Supplier Approval Process

Food businesses should be prepared to collect important food safety and quality…

Proposition 65

As required by Prop 65, California has published a list of chemicals…

Episode 1: The Importance of a Traceability Program

Traceability is the ability to follow, or trace, a finished product or…

Episode 7: CAPA Programs in GFSI

In facilities operating under an SQF program, the SQF Practitioner (or substitute…

Episode 6: Management and Auditing of the CAPA Program

An internal audit of a program focuses on the review of documentation…

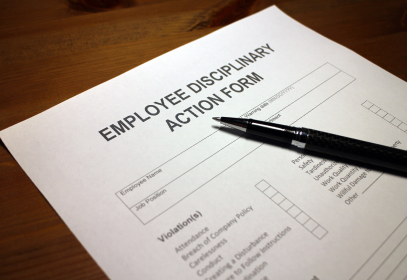

Episode 5: Impunity and Disciplinary Actions in CAPA Programs

Nonconformances caused by employee errors are to be expected in a food…

Episode 4: Deviations Involving Key Metrics

When a deviation or nonconformance event involving a key metric occurs, all…

Episode 3: Documenting Non-Conformances, Root Cause Analyses, Corrections, Corrective Actions, and Preventive Actions

When documenting the details of a deviation or nonconformance, begin by capturing…

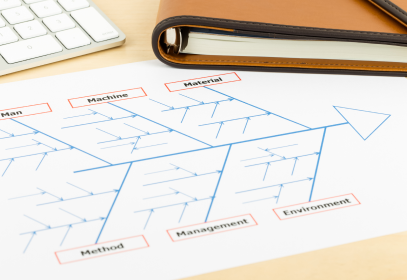

Episode 2: Root Cause Analysis, Corrective Actions and Preventive Actions

Corrections in a food facility can be described as immediate responses to…

Episode 1: Problematic Events in the Facility

Problematic events in a food facility can be categorized by process deviations…

Episode 6: Culture of Food Safety in GFSI

SQF is the newest GFSI program to adopt the Culture of Food…

Episode 5: The Walk-Through

What you will get out of this video is a how-to for…

Episode 4: Transforming Your Meetings

Site leadership should be involved in all Culture of Food Safety meetings….

Episode 3: Key Metrics

A key metric or performance indicator is something we measure within operations…

Episode 2: Structure and Delegation

This video describes how to properly set up organizational structure, and emphasizes…

Episode 1: Accountability & Core Values

We will discuss how it’s important to watch out for a sense…

Connecting Frontline Employees to a Culture of Food Safety

Introduction Across the food industry, developing or improving a culture of…

The Importance of Measurable Goals in a Culture of Food Safety

Introduction: Successful projects rarely happen by chance. In order to ensure that…

Breaking It Down: What You Need to Know about FDA’s Blueprint for the Future

Tech-enabled Traceability Technology-enabled traceability offers rapid tracebacks of contaminated products…

Key Changes in SQF Edition 9

Here are the key changes you will need to make to your…

Why Good Isn’t Good Enough

Many Fortune 100 and Fortune 500 grocery stores, distributors and quick service…

14 Questions To Ask When Hiring A Food Safety Consultant

Hiring a consultant that can deliver is critical. Over the years we’ve…

4 New Requirements In FSMA – Updates To HACCP Plans Required

Sometimes referred to as Hazard Analysis Risk-Based Preventive Control (HARPC), the new…

Questions about costs, timelines and requirements?

Contact Us Today for a Free Consultation

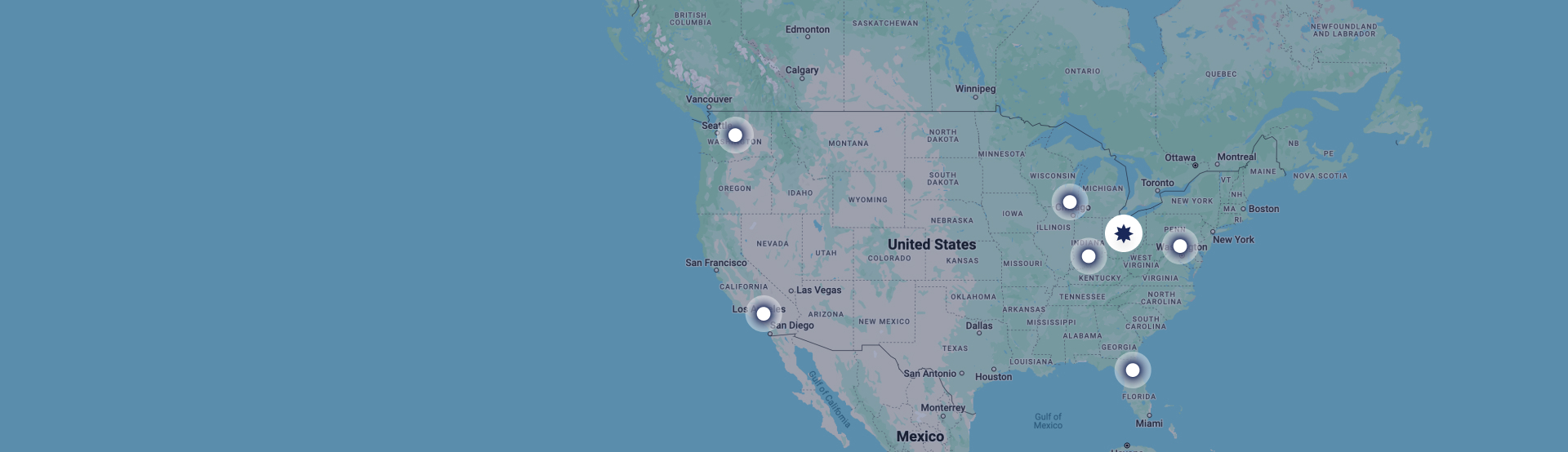

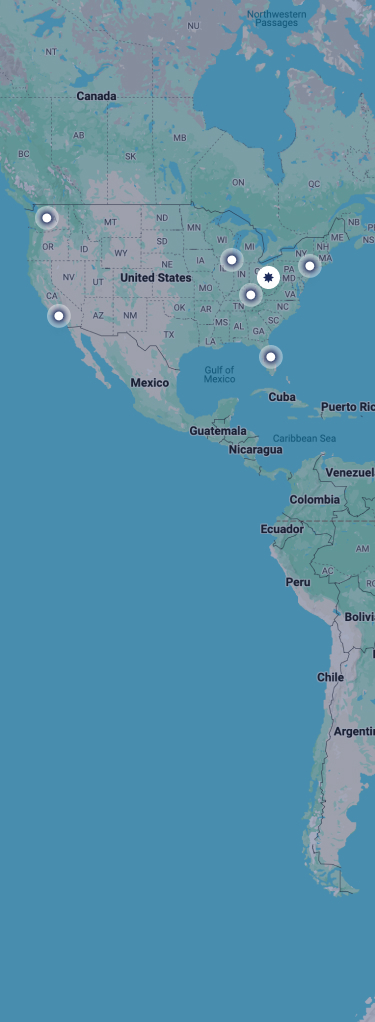

Available to travel for your project

-

Headquarters

-

Offices